China Shipbuilding Group's first N95 mask machine delivered!

"I have a mask machine, I have a plodder!"

At 17:25 on February 26th, on the official Weibo of China Shipbuilding Corporation, the news of providing relevant equipment to various enterprises and institutions in the battlefield against epidemic disease across the country quickly swiped the screen.

On February 27, China Ship delivered the batten press to the relevant enterprises in Liaoning Province and immediately put it into production and operation.

On February 28, Chinese ship delivered plane mask machine to CNPC and realized continuous production operation.

On February 29, Chinese ships rushed to help a group of batters in Hubei.

On March 2, the Chinese ship delivered plane mask machine to Sinopec.

On March 3, Chinese ship delivered N95 mask machine to CNPC.

The frequent reports indicate that China Shipbuilding Group's mask machine and plodder have achieved stable mass production and continuous delivery. In particular, Chinese ships have joined forces with central oil companies such as PetroChina and Sinopec to form a national team for the production of epidemic prevention materials, and quickly realized the large-scale production of resumption ŌĆ£weaponsŌĆØ such as masks. At the critical juncture of the war epidemic, the role of ballast stones was highlighted, which caused a lot of heat. Discuss--

"Companies that make aircraft carriers also make masks!"

"Practice the mission of the central SOE, call immediately, tackle the problem urgently, and overcome the epidemic."

"China Power, China Efficiency!"

Central enterprise mission must be achieved

Since the outbreak of the epidemic, the demand for masks and protective clothing has increased dramatically, and mask machines and beading machines (for protective clothing processing) are also difficult to find. From the source to find ways to expand production capacity, state-owned central SOEs bravely carry heavy burdens.

According to the decision-making and deployment of the State Council's office meeting, the State-owned Assets Supervision and Administration Commission of the State Council arranged relevant central enterprises to undertake special tasks of emergency research and development of key equipment for medical supplies production, and China Shipbuilding Corporation carried out emergency research and production of key anti-epidemic production equipment such as mask machines and bead presses.

The urgent task of prevention and control was urgent. The party group of China Shipbuilding Group took the special task as an important political task, and immediately organized and established a special task work leading group. The main leaders of the group company personally deployed and directed forward. In order to ensure the successful completion of the special task, the eighth affiliated hospital is clarified as the special task technical responsibility unit. The eighth affiliated hospital and Hanguang Heavy Industry Co., Ltd. jointly conduct prototype development and mass production. Relevant departments at the headquarters make every effort to organize and coordinate special tasks.

Under the guidance, support and assistance of the State-owned Assets Supervision and Administration Commission of the State Council, the China Shipping Group organized the task-bearing units to advance their work according to the state of wartime. On the day of February 11, the leaders of the headquarter department of the Group were assigned to organize a team of technical personnel to conduct research, exchange and learning, and carried out the program demonstration, technical design and improvement, production commissioning, and mass production preparation, etc., while developing, preparing, and producing. , Quickly completed the solidification of the technical status and the preparation of nearly 2,000 process documents, and simultaneously carried out the batch production and outsourcing procurement of more than 1,600 kinds of parts and a total of more than 130,000 parts.

Enter wartime

The harder it gets, the more we move forward. During the development and production process, China National Shipbuilding Corporation took the initiative to "conditional requirements, to create conditions without conditions," to overcome the urgency of the task in a complicated epidemic situation, the inability of personnel to arrive on time, and the restrictions on supplier resumption. Difficulties, doing everything possible to advance the work, all relevant enterprises unite, cooperate and go all out, while researching, preparing, and producing, ensuring the completion of the task.

"We must rise to the challenge and co-ordinate the resources of the hospital, make use of the technical advantages, fight against every second, and provide protection for the epidemic prevention and control. At present, we have successfully completed the development of prototypes of type 3 equipment and the performance indicators fully meet the design requirements. Yinhua reports to the party group of the group company.

On February 24, a special task video conference was held at China Shipbuilding Headquarters and related companies. Through the video, Lei Fanpei, Secretary of the Party Committee and Chairman of China Shipbuilding Corporation, inspected the mask and machine assembly and commissioning workshop of the Eighth Hospital, Hanguang Heavy Industry's mask machine, machine and processing workshop, and assembly and commissioning workshop. The energy and electric box production workshop heard the report of the progress of the special task by the main responsible comrades of the task unit, and gave instructions for the follow-up arrangement of the special task.

"The development of equipment prototypes in such a short period of time reflects the spirit of the military industry enterprise to win and win at critical moments." Lei Fanpei emphasized that we must continue to grasp the production progress, give play to advanced manufacturing advantages, further stimulate potential, and expand Production capacity to ensure that key equipment for the production of epidemic prevention materials is delivered on time and with quality.

In this special task, the Eighth Academy is both a technical responsibility unit and a production unit, playing a dual role of technical design and production delivery. In the case of a shortage of process and technology reserves, a shortage of raw materials and accessories, and a shortage of skilled equipment workers, the Eight Academy of Technology Tackling Team implemented a 24-hour working system to analyze the production process, quickly formed a project implementation plan, work plan, and launched urgently. Technical status solidification, assembly and commissioning work, while supporting the prototype team in the group through remote communication technologies such as WeChat. On February 21, the N95 mask machine, flat mask machine and batten prototype were rolled off the production line.

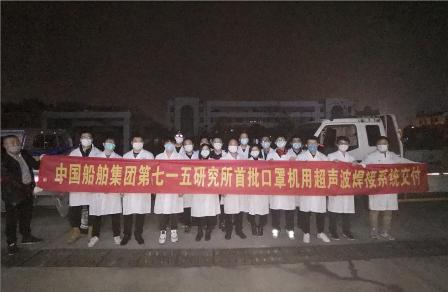

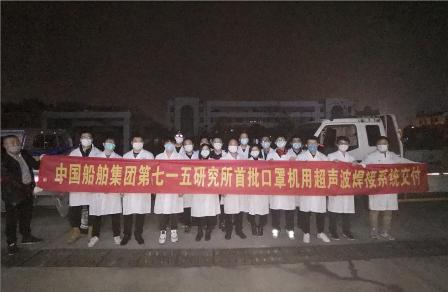

As a production and supply unit, in order to expand production capacity as quickly as possible, the Party Branch of the Eight Academy of Pengli Intelligent Manufacturing Co., Ltd. issued a "red assembly order" to all party members, and then issued a "build a hard-core organization at Pengli speed" to all employees. Wartime mobilization initiative. Everyone took the initiative to join us in this battle. In the case that most of the outsourced suppliers could not resume work normally, the Eighth Academies internally mobilized the military and civilian products, cooperated with the main outsourced suppliers externally, organized nearly 800 people to resume work, and jointly implemented the production of self-made parts. In order to ensure progress and quality, special personnel were sent to over 30 outsourced units to supervise production. At 23:00 on February 27, the first batch of batters for the Eighth Academy was delivered. At 4 am on February 28, the first batch of mask machines for the Eighth Hospital was delivered. At 23:00 on March 3, the first batch of N95 mask machines of the Eighth Hospital was delivered.

"This special task production is a big test of whether the factory can stand on wartime, quickly organize mobilization, and speed up the conversion of military and civilian production. We must be confident and work hard to complete the special task." Secretary of the Party Committee of Hanguang Heavy Industry, Chairman Wang Mengjun said.

As the main production unit of this special task, Hanguang Heavy Industry urgently mobilized and set off immediately. In order to ensure that the production capacity of military products was switched to the production and development of mask machines as soon as possible, after receiving a special task at 13:00 on February 11, Hanguang Heavy Industry urgently set up a special agency to push the production of imported mask machine intelligent equipment. Quickly analyze personnel structure, actively communicate and coordinate with Handan City, and resume work in batches. While doing a good job in epidemic prevention and control, five technical research groups were formed. Develop a thorough plan, implement responsibilities at all levels, clarify timetables and roadmaps, and hold at least 2 scheduling meetings a day to solve problems on the spot.

The Party branch of the Mechanical Engineering Division of Hanguang Heavy Industry held an emergency meeting before resuming work, requiring all party branches to cooperate closely to complete the epidemic prevention and control and production tasks; each working group is equipped with at least "one backbone and one party member" to coordinate and solve each In this kind of problem, party members are at the top.

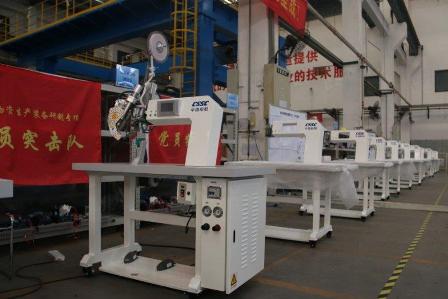

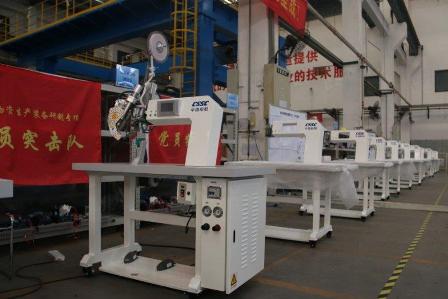

The data shows that Hanguang Heavy Industry has more than 100 designers, 450 operators, and 200 commissioners who have been engaged in this battle without smoke. There are 376 sets of equipment in 4 production workshops and 3 commissioning workshops running around the clock. On the 38,000 square meters production site, the roar of the machines is one after another. The machining, sheet metal, assembly, and commissioning workshops are fully operational, and more than 100 management personnel, including procurement, finance, and scheduling, insist on shifts and on-site positions to ensure that they can meet on-site production as soon as possible. Technicians prepare more than 1,000 process files in 2 days, and the production of machining parts, sheet metal parts, standard parts and other parts is progressing at the same time ...

At the same time as resumption of work and production, materials procurement is under great pressure. In order to solve the worries of production, the company decided to form nine key research teams for purchasing parts, raw materials, and other procurement tasks, and promoted them by category and sold them item by item to complete the supply tasks at any cost. At present, 1,343 kinds of purchased items and more than 100,000 purchased items have all completed the procurement plan and issued.

Ultrasonic welding equipment is widely used in the non-woven fabric welding production process. It is a key supporting component of the mask production line. For example, a "sewing machine" without a thread can sew masks efficiently and accurately. This device is one of the flagship products of 715 ultrasound companies. In response to the urgent need for the prevention and control of production of materials, the 715 party committees urgently deployed, coordinated the research and production resources of the ultrasound company and the institute, adjusted the layout of production capacity in a timely manner, and specially opened a piezoelectric ceramic component production line, and deployed more than 40 sets of production equipment and a Batch of special mold fixtures, emergency extraction transducer production personnel, electrical equipment and system joint adjustment personnel, quality inspection personnel, the staff size has been increased by three times, and the three shift mode is used for production. Since the resumption of work on February 15, the production capacity of ultrasonic welding equipment has reached 5 times the original.

Demonstrate the true nature of the military

The sea was flowing, Fang showed his true colors. The China Shipbuilding Group did not humiliate its mission or carry out its special tasks, fully demonstrated the strong scientific and technological innovation strength and emergency mobilization ability of this enterprise's "national team", which fully reflected the military industry group's "dare to fight, can fight, win victory" Excellent style, interpreting "the most trusted force of the party and the state" with practical actions.

Ensure plan execution. China Shipbuilding Corporation has established a vertical command communication coordination mechanism that runs from the group headquarters to the production team. It holds daily working meetings at all levels and production scheduling coordination meetings, and adjusts work plans on a rolling basis to ensure the full implementation of the development and production plan for type III equipment. Bring into play the role of grassroots party organizations as the fortress of fighting and the role of pioneers as party members, organize the formation of "Party Commando", work 24 hours without intermittent shifts, take the lead in overtime and invest in special tasks in research and production.

Strict quality control. Correctly handle the relationship between quality and promotion, formulate quality assurance plans, and strictly control process from technical design, production and processing, outsourcing, installation and commissioning in accordance with military product quality requirements to ensure that the quality of delivered products is excellent. The equipment runs stably and reliably.

Coordinated resource guarantee. Newly purchased 28 production equipments, temporarily converted production of some military production capacity to support the development and production of mask machines, to ensure that self-made parts and assembly and debugging capabilities meet the requirements of special tasks; the headquarters of the Group's headquarters in Nanjing, Handan and other local government support task units resumed production and organized management , Technology, production, procurement and other departments have accumulated nearly 2,000 people into research and production.

Work closely together. In the epidemic situation, the supply of outsourcing kits and test machine raw materials was tight. The group company dispatched internal resources and organized CSSC Oasis, CSSC Jiujiang and other group members to carry out emergency production of some parts; at the same time, actively coordinated nearly 100 suppliers to implement raw materials Purchasing and processing of outsourced parts, on-site supervision of production and special car transportation guarantee to ensure that production supporting materials are in place as planned.

Lei Fanpei, Secretary of the Party Committee and Chairman of China Shipbuilding Group, said that in the next step, China Shipbuilding Group will effectively fulfill the responsibility mission of central enterprises and, in accordance with the deployment requirements of the State-owned Assets Supervision and Administration Commission of the State Council, will continue to take the initiative to take responsibility, perform due diligence, We will go all out to complete the assembly, debugging and delivery of mass production equipment on schedule, and resolutely win the battle against epidemic prevention and control and the scientific research and production.

|