Current Location’╝ÜHome - News - Industry

|

|||

| Published’╝Ü2021.03.15 News Sources’╝ÜQingdao Gute Ship Supplies Co., Ltd. Views’╝Ü | |||

|

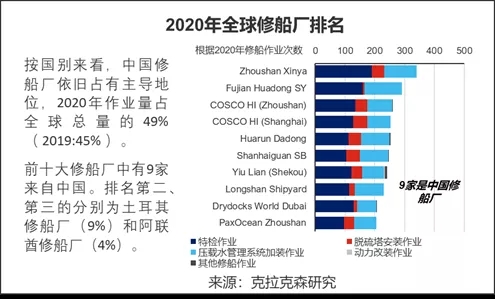

4 Zhoushan Shipyard "Top List"! Chinese shipyards dominate the global market for ship repair

Recently, the British study released clarkson 2020 repairing yard in the world rankings, repairing work according to 2020 statistics, in the global top ten repairing yard, nine Chinese shipyard, and zhoushan has four ships, zhoushan xin and ship building co., LTD., zhoushan cosco shipping heavy industry, zhoushan longshan shipyard co., LTD., Pacific Ocean engineering (zhoushan) co., LTD., which topped the xin and ship. The other five Chinese shipyards are Fujian Huadong Shipyard, Shanghai COSCO Shipping Heavy Industry, Shanghai China Resources Dadong, Shanhaiguan Shipbuilding Heavy Industry and Shekou Youlian.

Located in putuo six horizontal xin ship building co., LTD is a private Chinese largest shipyard in the shipyard, rebuild after relocation, the financial crisis, the industry transformation and upgrading of strategic cooperation, nodes, and other important development since its establishment, xin the ship had already passed 19 years, has grown to have three production base, "four dock ten berth capacity, at the top of the world ship repairing enterprises 7, ranks the first in the industry leading private ship repairing company. Since 2014, Xinya has adjusted its production structure, gradually shifting its production structure from the maintenance of low value-added ships such as bulk carriers to the maintenance of high value-added ships such as oil chemical ships, wind power installation ships and mud suction ships. At the same time, the enterprise rose to the challenge, improved the hardware facilities and management level, started to build "6S" standard workshop, the total investment of more than 100 million yuan. Up to now, the company has built 6 "6S" workshops. In addition to repair, Xin Ya also seeks the transformation of business. To this end, Xinya seized the market opportunity of increasing demand for desulfurization device installation and successfully undertook the refit order of desulfurization tower. Facing the large amount of refit project, tight dock repair period, long berthing time, high technical difficulty and shortage of human resources, the company developed and invented the ship desulphurization tower installation device platform and hoisting device by itself, which not only guaranteed the refit progress of ship desulphurization tower, but also improved the production efficiency and safety. According to Clarkson survey data, Zhoushan Xinya Shipbuilding Co., Ltd. has entered the world's top 10 desulphurization equipment refit business. Due to the implementation of the international ship desulfurization standard in 2020, large shipping companies have ushered in a big year for ship repair. Xinya Shipyard's annual repair volume exceeded 400 ships in 2020.

Zhoushan COSCO Marine Heavy Industry Co., Ltd. continues to deeply practice the concept of green environmental protection, and actively promotes the ultra-high pressure water rust removal process to realize the integrated vacuum recovery of wastewater. Make open air spraying operation VOCs collection and recycling tooling, speed up the upgrading of the painting room, promote VOCs organized emissions; We have signed strategic cooperation agreements with Zhejiang Fasco and COSCO Jodun to strengthen the innovation of environmental protection process and independent research and development of environmental protection technology and strive to build a "garden factory". In 2020, the company was identified as "Zhoushan Green Ship Repair Demonstration Enterprise" and "Zhejiang Cleaner Production Enterprise". Zhoushan cosco shipping heavy industry continues to increase green ship repairing, wisdom, ship repairing, development and application of new technologies such as combining "zhoushan ship in the work of 5 g + wisdom", positive and China classification society (CCS), China mobile (CMCC) using 5 g + AR remote inspection technology, 5 g + uavs view of inspection technology, the remote for the first time to complete 230000 ore carrier "benevolence" wheel to complete the annual inspection of the ship. Under the global COVID-19 epidemic crisis, the value of remote inspection, service and guidance has been highlighted to provide customers with a more transparent and traceable on-site control mechanism for ship repair.

Starting from around 2015, the depressed international shipping situation forced the transformation and upgrading of ship repair and construction enterprises. Longshan Shipyard also began to adjust and improve the industrial structure, from the original bulk carrier maintenance of the main product structure gradually to the maintenance of oil tanker, cement rol-off ship and other high value-added ships. At the same time, the shipyard has increased investment in technological upgrading, promoted green ship repair, introduced high-end technical talents, and improved the professional and technical capabilities of front-line staff. The shipyard has gradually transformed from routine repair to high technical content modification business and high value-added ship maintenance. Since last year, Longshan Shipyard has seized the opportunity of refit desulphurization tower and cooperated with Shandong Peisen Environmental Protection Technology Co., Ltd. to build desulphurization tower project, with a total investment of nearly 100 million yuan, and started the desulphurization tower manufacturing project of 50 million yuan. On March 18, last year, Zhoushan Longchuan Environmental Protection Technology Co., Ltd. completed the first set of desulfurization tower delivery ceremony held in Zhoushan Longshan Shipyard Co., Ltd.

Pacific Ocean Engineering (Zhoushan) Co., Ltd. is one of the six leading Marine and offshore equipment enterprises in Zhoushan, which is a wholly-owned subsidiary of Singapore Pacific China Group (Zhoushan) Private Co., Ltd., a subsidiary of Singapore Kuo Brothers Group. The company has one of the largest shipyards in Zhoushan, which can undertake the maintenance of 400,000-ton super-large ore carriers. At present, the company has transformed into a repair shop with ship repair as its main business, mainly targeting the repair markets of Japan and South Korea, Taiwan and Southeast Asia. The ship types it receives range from bulk carriers, container ships, tankers to ultra-large ore carriers. In recent years, international organizations have strict with green ship repairing, internationally operating fleet faces many ship repairing demand of environmental protection regulations, the Pacific Ocean engineering (zhoushan) co., LTD., to seize the sulfur limit "of the international business opportunities, give full play to the professional and technical expertise, expand their business, complete ship equipped with exhaust gas desulfurization device project so far, a total of 54 sets. In 2020, Pacific Ocean Engineering (Zhoushan) Co., Ltd. repaired and completed 180 ships, with a year-on-year growth of 25%, and the output value reached 900 million, with a year-on-year growth of 38%.

In addition to the above 4 companies, there is actually another ship repair enterprise in Zhoushan, Zhoushan Wanbang Yongyue Ship Repair Co., Ltd. Although Wanbang Yongyue is not listed in the top 10 this time, Zhoushan Wanbang Yongyue is definitely the "class representative" of China's ship repair industry and the forerunner of the concept of "green ship repair" in China.

According to statistics, in 2020, Zhoushan will repair 1,900 foreign ships, with an output value of 5.3 billion yuan, an increase of 20%. The high profit margin is behind the green ship repair. Over the years, Zhoushan ship enterprises focus on the use of high pressure water rust removal and other green advanced ship repair technology, effectively reduce the cost, at the same time seize the desulfurization tower refit business opportunities in the past two years, change the conventional ship repair ideas, choose more such as oil tanker, cruise ship and other high value-added ship repair, profit is more than ten times higher. At the same time, cosco xin heavy industry, the ship's main ship companies and adjust measures to local conditions to compile the implementation of the ship in the work of mechanical and electrical work area 6 s workshop management standard "" ship ultra-high pressure water jet process standard" technical specification for the ship building steel enterprise use of green ship repairing concrete technical regulations, standards, greatly enhance the enterprise core competitiveness. In recent years, the requirements of international organizations for green ship repair have become stricter. The international operating fleet is faced with the requirements of many ship environmental protection regulations for ship repair, mainly in the installation of desulfurization tower and the installation of ballast water treatment system. Therefore, in the past year, Xinya Shipbuilding, Zhoushan COSCO Shipping Heavy Industry and Longshan Shipyard undertook a large number of desulfurization tower installation and ballast water treatment system installation business, ushering in the peak of ship repair. |

|||

| This Paper Is Divided Into 1 Page | |||

| Next:Guangxi's first hydrogen energy ship project led by Guilin Wuzhou was officially launched | |||

| Previous:The first "Zhoushan Ship Type" multi-functional maritime service ship was launched | |||